Revolutionizing Industrial Control with Raspberry Pi: A Comprehensive Guide

I. Introduction

The industrial control field is undergoing a significant transformation, thanks to the versatile and cost-effective Raspberry Pi. This comprehensive guide explores how Raspberry Pi is revolutionizing industrial control, covering its key components, capabilities, applications, advantages, disadvantages, trend analysis, and the future it promises.

Raspberry Pi: A Raspberry Pi is a compact single-board computer designed by the Raspberry Pi Foundation, offering a wide range of features and functions.

Industrial Control: Industrial control is the discipline that oversees the operation, monitoring, and automation of various processes and equipment in industries, enhancing efficiency and safety.

II. Core Components

The Raspberry Pi's core components are the building blocks of its impact in industrial control:

CPU: Raspberry Pi boards are powered by Broadcom's ARM-based CPU, which provides the computational strength necessary for running various industrial applications.

RAM: The onboard RAM varies across Raspberry Pi models but is critical for multitasking and handling substantial datasets.

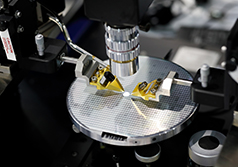

I/O Ports: General Purpose Input/Output (GPIO) pins enable interfacing with sensors, motors, and other devices integral to industrial control systems.

Connectivity: With Ethernet and Wi-Fi capabilities, Raspberry Pi can efficiently communicate with other devices and central control systems.

III. Capabilities and Applications

Capabilities of Raspberry Pi

Raspberry Pi offers an array of characteristics that make it an ideal choice for revolutionizing industrial control:

Affordability: Raspberry Pi boards are cost-effective, reducing the financial burden for both small and large-scale industrial applications.

Compact Size: The small form factor of Raspberry Pi permits easy integration into constrained spaces, control cabinets, and industrial machinery.

Versatility: It supports multiple operating systems, primarily Linux-based distributions, enabling adaptation to diverse control scenarios.

Expandability: GPIO pins and USB ports facilitate connections to sensors, cameras, and various peripherals for comprehensive control.

Applications in Industrial Control

Raspberry Pi's applications in industrial control are extensive and ever-evolving:

Data Logging: It collects data from sensors, stores it, and provides insights for monitoring and optimizing industrial processes.

Automation: Raspberry Pi can be programmed to control motors, actuators, and other equipment, reducing manual labor and enhancing safety.

Remote Monitoring: It enables real-time monitoring of industrial systems from remote locations, improving troubleshooting and maintenance.

IoT Integration: Raspberry Pi serves as a gateway for Internet of Things (IoT) devices, facilitating data exchange and advanced analytics.

IV.Advantages:

Cost-Effective: Raspberry Pi provides a budget-friendly solution, reducing the overall investment required for industrial control systems.

User-Friendly: It is accessible to beginners and professionals alike, thanks to the extensive Raspberry Pi community and online resources.

Customization: Its open-source nature allows for extensive customization and the development of applications tailored to specific industrial needs.

V.Disadvantages:

Limited Processing Power: Raspberry Pi may not be suitable for high-complexity or real-time applications, where dedicated industrial control hardware is required.

Durability: Industrial environments can be harsh, and Raspberry Pi boards may not be as rugged as industrial-grade control systems.

Trend of Raspberry Pi

The adoption of Raspberry Pi in industrial control is on the rise, driven by its affordability and versatility. As technology continues to advance, we can expect further improvements in processing power and durability, making it an even more compelling choice for a broader range of industrial applications.

VI.Conclusion

Raspberry Pi is revolutionizing the industrial control field, offering an accessible, cost-effective, and versatile solution for automation and monitoring. While it may not replace dedicated industrial control systems in all scenarios, it certainly has a significant role, particularly in smaller-scale and budget-conscious projects. As the Raspberry Pi ecosystem continues to evolve, its influence on industrial control is poised to grow, promising a brighter and more automated future.

Subscribe to Us !

-

LV71081E-MPB-E

LV71081E-MPB-Eonsemi

-

LMK00334RTVRQ1

LMK00334RTVRQ1Texas Instruments

-

PI6C557-03LEX

PI6C557-03LEXDiodes Incorporated

-

PCM1753DBQR

PCM1753DBQRTexas Instruments

-

ADS1204IRHBT

ADS1204IRHBTTexas Instruments

-

MCP4018T-104E/LT

MCP4018T-104E/LTMicrochip Technology

-

T4F49C2

T4F49C2Efinix, Inc.

-

.jpg) A40MX02-PLG44

A40MX02-PLG44Microchip Technology

-

ATF16V8C-7PU

ATF16V8C-7PUMicrochip Technology

-

SC-13048Q-A

SC-13048Q-AGHI Electronics, LLC