Ensuring Quality in Electronic Component Manufacturing

In today's fast-paced technological landscape, electronic devices have become an integral part of our daily lives, permeating every industry and facet of society. From smartphones to medical equipment, from automotive systems to communication devices, electronic components play a pivotal role in ensuring functionality and efficiency. As the demand for cutting-edge electronics continues to rise, so does the importance of ensuring quality in electronic component manufacturing. This article delves into the significance of quality control in the manufacturing process, shedding light on techniques, certifications, and best practices that guarantee the production of reliable and high-performance components.

Introduction: The Crucial Role of Quality Control

Quality control serves as the cornerstone of successful electronic component manufacturing. In an industry driven by innovation and rapid advancements, the adherence to stringent quality standards ensures that the components produced are dependable, safe, and high-performing. Without effective quality control measures, the potential risks of product failure, performance inconsistencies, and safety hazards increase substantially.

The Impact of Inferior Components: Reliability and Performance Concerns

When subpar electronic components find their way into devices, the consequences can be dire. Inferior components can lead to compromised reliability, causing products to malfunction or fail prematurely. Additionally, performance inconsistencies may arise, affecting the overall user experience and potentially tarnishing a company's reputation. Ensuring quality in manufacturing directly addresses these concerns, mitigating risks and ensuring the longevity and performance of electronic devices.

Techniques for Ensuring Quality in Electronic Component Manufacturing

3.1 Statistical Process Control (SPC)

SPC involves the real-time monitoring and control of manufacturing processes to detect any deviations from the desired specifications. By collecting and analyzing data at various stages of production, manufacturers can identify trends, detect anomalies, and make necessary adjustments to maintain consistent quality.

3.2 Failure Modes and Effects Analysis (FMEA)

FMEA is a systematic approach used to identify potential failure points in a product or process and assess their potential impact. This proactive technique enables manufacturers to anticipate and address potential issues before they can impact the final product.

3.3 Design of Experiments (DOE)

DOE is a methodical approach to experimentation that allows manufacturers to systematically vary factors in a controlled manner to determine their effect on a product's performance. This technique aids in optimizing manufacturing processes and identifying the ideal conditions for producing high-quality components.

Certifications: Setting Industry Standards for Quality

4.1 ISO 9001: Quality Management Systems

ISO 9001 certification signifies a commitment to maintaining consistent quality and continuous improvement. Companies adhering to this standard demonstrate their dedication to meeting customer expectations and delivering reliable products.

4.2 IPC-A-610: Acceptability of Electronic Assemblies

IPC-A-610 certification provides guidelines for evaluating the acceptability of electronic assemblies. It outlines criteria for soldering, component placement, and other assembly processes, ensuring that products meet the necessary quality standards.

4.3 RoHS Compliance: Restriction of Hazardous Substances

RoHS compliance restricts the use of hazardous substances in electronic products. This certification not only promotes environmental sustainability but also ensures the safety and quality of electronic components.

Best Practices for Achieving Optimal Quality in Manufacturing

5.1 Supplier Collaboration and Auditing

Collaboration with trusted suppliers and regular audits of their manufacturing processes contribute to the overall quality of electronic components. Clear communication and transparency in the supply chain are essential for maintaining consistent standards.

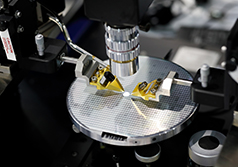

5.2 In-Process Inspections and Testing

Regular inspections and testing during the manufacturing process help identify defects and deviations early on, preventing the production of faulty components and reducing the likelihood of defects reaching the end user.

5.3 Continuous Improvement and Kaizen Philosophy

The implementation of continuous improvement practices, inspired by the Kaizen philosophy, fosters a culture of constant learning and enhancement. By seeking opportunities for refinement, manufacturers can consistently elevate the quality of their products.

Enhancing Reliability: Environmental and Endurance Testing

To ensure the reliability of electronic components, rigorous environmental and endurance testing is crucial. Exposing components to extreme conditions and stress tests simulates real-world usage scenarios, identifying potential weaknesses and areas for improvement.

Conclusion: Elevating Electronic Manufacturing Through Quality Control

In the dynamic landscape of electronic component manufacturing, quality control stands as a paramount factor in producing components that meet and exceed customer expectations. By employing advanced techniques, adhering to industry certifications, and implementing best practices, manufacturers can ensure the creation of reliable, high-performance electronic components that drive technological innovation forward.

FAQs (Frequently Asked Questions)

1. Why is quality control essential in electronic component manufacturing?

Quality control ensures the production of dependable and high-performing components, minimizing risks of failure and performance issues.

2. What is ISO 9001 certification, and why is it significant?

ISO 9001 certification demonstrates a commitment to consistent quality and continuous improvement, instilling confidence in customers.

3. How does RoHS compliance contribute to electronic component quality?

RoHS compliance ensures the absence of hazardous substances, promoting both environmental sustainability and product safety.

4. What role does supplier collaboration play in quality assurance?

Supplier collaboration and audits maintain transparency and consistency in the supply chain, enhancing overall product quality.

5. How does the Kaizen philosophy benefit electronic manufacturing?

The Kaizen philosophy fosters continuous improvement, allowing manufacturers to consistently enhance the quality of their products.

Subscribe to Us !

-

LV71081E-MPB-E

LV71081E-MPB-Eonsemi

-

LMK00334RTVRQ1

LMK00334RTVRQ1Texas Instruments

-

PI6C557-03LEX

PI6C557-03LEXDiodes Incorporated

-

PCM1753DBQR

PCM1753DBQRTexas Instruments

-

ADS1204IRHBT

ADS1204IRHBTTexas Instruments

-

MCP4018T-104E/LT

MCP4018T-104E/LTMicrochip Technology

-

T4F49C2

T4F49C2Efinix, Inc.

-

.jpg) A40MX02-PLG44

A40MX02-PLG44Microchip Technology

-

ATF16V8C-7PU

ATF16V8C-7PUMicrochip Technology

-

SC-13048Q-A

SC-13048Q-AGHI Electronics, LLC