Demystifying Electronics: Understanding the Difference between Integrated Circuits and Chips

Introduction:

In the fast-paced world of electronics, terms such as "integrated circuit" and "chip" are commonly used interchangeably, leading to confusion among enthusiasts and professionals alike. While both play pivotal roles in the functioning of electronic devices, they are not synonymous. This article aims to unravel the distinctions between integrated circuits and chips, shedding light on their unique characteristics and applications.

What is a Integrated Circuit?

An integrated circuit (IC), often referred to as a microchip, is a miniature electronic circuit that comprises a multitude of interconnected electronic components such as transistors, resistors, capacitors, and diodes. These components are fabricated on a tiny semiconductor wafer, typically made of silicon. The integration of these components onto a single chip allows for the creation of complex electronic systems, ranging from microprocessors to memory chips.

Key Features of Integrated Circuits:

Miniaturization: The hallmark of integrated circuits is their ability to pack a significant number of electronic components into a compact form. This miniaturization is a result of advancements in semiconductor manufacturing technology, enabling the creation of intricate circuits on a small piece of semiconductor material.

Functionality: Integrated circuits are designed to perform specific functions within electronic devices. For example, a microprocessor is an integrated circuit that serves as the brain of a computer, executing arithmetic and logic operations. The functionality of an integrated circuit is determined by its design and the arrangement of its components.

What is a Chip?

The term "chip" is a colloquial expression often used to describe a semiconductor device that can range from a single integrated circuit to a more complex assembly of multiple integrated circuits on a single substrate. In essence, a chip can be considered a broader category that encompasses various types of semiconductor devices.

Key Features of Chips:

Versatility: Unlike integrated circuits, which are specific to certain functions, chips can be general-purpose or application-specific. For example, a microcontroller chip may include a processor, memory, and input/output peripherals, making it suitable for a wide range of applications.

Multifunctionality: Chips may consist of more than one integrated circuit, each serving a distinct purpose. This enables the creation of multifunctional devices with diverse capabilities. For instance, a system-on-a-chip (SoC) integrates various components, such as a processor, memory, and communication interfaces, into a single chip.

Differences between Integrated Circuits and Chips

1. Different shapes and packages

Integrated circuits (ICs) and chips, though often used interchangeably, represent distinct entities in the realm of semiconductor technology. A chip, typically produced on the surface of semiconductor wafers, epitomizes a methodology for the miniaturization of circuits, encompassing semiconductor devices and passive components. The widely adopted Dual In-Line Package (DIP) standard, employed by most chip manufacturers, defines a rectangular package with pins precisely spaced apart at intervals of 0.1 inches and 2.54 mm, facilitating the assembly of multiple chips on a board. The DIP's grid configuration of 0.1"x0.1" pitch ensures alignment accuracy. While the DIP standard has endured, allowing for the accommodation of higher pin counts with the advent of Medium-Scale Integration (MSI) and Large-Scale Integration (LSI) chips, the fundamental design has remained unchanged.

Conversely, an integrated circuit is a diminutive electronic component or device featuring intricate circuitry. These ICs are encapsulated in protective packages for ease of handling, assembly onto printed circuit boards, and safeguarding against environmental factors. Diverse package types, often standardized by organizations such as JEDEC and ProElectron, categorize these encapsulations. Additionally, unique, non-standardized packages exclusive to specific manufacturers exist. The culmination of the IC manufacturing process involves packaging before the product undergoes testing and is dispatched to the end-user.

In certain instances, specialized integrated circuit dies can be directly affixed to substrates without intermediary connectors or carriers. The flip-chip configuration employs solder bumps for direct IC-to-substrate connections. Contrary to conventional wire bond connections, flip-chip technology utilizes thicker and elongated metallization pads, facilitating external circuit connections. Protective measures against moisture include additional packaging or epoxy fill for components employing "bare" chips.

The contact terminals or pins of an integrated circuit extend from its body, housed in a robust insulating material with high thermal conductivity. Various IC package types are available to accommodate distinct pin configurations. Examples include the traditional Dual In-Line Package (DIP), the modern Plastic Quad Flat Package (PQFP), and the advanced Flip Chip Ball Grid Array (FCBGA). Understanding these nuanced differentiations is imperative in navigating the intricacies of semiconductor technology and the assembly of electronic systems.

2. Differences in production technology

The manufacturing processes for integrated circuits (ICs) and chips diverge significantly, reflecting the distinct nature and functionality of each. Integrated circuits, being the core electronic components, undergo intricate fabrication processes on semiconductor wafers.

The Fabrication of Integrated Circuits Involves Several Key Steps:

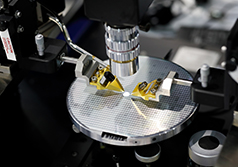

Wafer Fabrication (Front-end Process): The process initiates with the production of semiconductor wafers, typically composed of silicon. These wafers undergo extensive cleaning and preparation before the deposition of various layers, including the creation of the active regions where transistors and other components will be formed.

Photolithography: A crucial step, photolithography employs light-sensitive materials to transfer circuit patterns onto the wafer's surface. This process defines the intricate circuitry that constitutes the integrated circuit.

Etching and Deposition: Chemical etching removes unwanted materials, while deposition processes add new layers to build up the required structures. This cycle is repeated to create the multiple layers necessary for the integrated circuit's functionality.

Doping: Introducing specific impurities, or doping, is a critical step to alter the electrical properties of semiconductor materials. This process helps create transistors and other semiconductor devices on the wafer.

Annealing: Thermal processes, such as annealing, optimize the properties of the fabricated layers, ensuring the integrity and functionality of the integrated circuit.

Back-end Processes: After the front-end processes, the wafer undergoes back-end processes, including the application of metal layers for interconnections, the creation of bonding pads, and the addition of passivation layers for protection.

In contrast, the term "chip" is more encompassing, referring to a semiconductor device that can include one or more integrated circuits. The manufacturing process for chips involves the assembly and encapsulation of these integrated circuits into a cohesive unit.

The chip manufacturing process involves the following steps:

Die Attach: The individual integrated circuit dies are attached to a substrate, often using adhesive materials.

Wire Bonding or Flip-Chip Bonding: In wire bonding, thin wires connect the integrated circuit to the substrate. In flip-chip bonding, solder bumps establish direct connections between the integrated circuit and the substrate.

Encapsulation: The assembled components are encapsulated in protective materials, such as plastic or ceramic, forming the final chip package. This encapsulation safeguards the components from environmental factors and physical damage.

Testing: The completed chips undergo rigorous testing to ensure functionality and reliability. This step is crucial to identify and rectify any defects before the chips are deployed in electronic devices.

Understanding these distinct manufacturing processes is pivotal in appreciating the intricacies of semiconductor technology and the production of electronic components that power the modern world.

3. Differences in Effects

The differences between integrated circuits (ICs) and chips extend beyond their manufacturing processes and physical structures; they also manifest in their effects on electronic systems and devices.

Functionality and Complexity:

· Integrated Circuits (ICs): ICs are designed to perform specific functions within electronic devices. They can range from simple circuits, like operational amplifiers, to highly complex systems such as microprocessors. The functionality of an IC is tailored to its intended application, and it typically represents a specific building block in an electronic system.

· Chips: The term "chip" is more generic and can refer to a single IC or a combination of multiple ICs on a substrate. Chips can encompass a broader range of functionalities, allowing for the integration of diverse functions within a single package. This versatility makes chips suitable for applications that require multiple functionalities, like microcontrollers or system-on-a-chip (SoC) solutions.

Versatility and Customization:

· ICs: Integrated circuits are often application-specific, meaning they are designed for a particular purpose. While some ICs are versatile and find use in various applications, many are customized to meet specific requirements, optimizing performance for a particular task.

· Chips: Chips, being a more inclusive term, can house a variety of integrated circuits and passive components. This allows for greater customization and adaptability to different applications. Engineers can integrate multiple ICs with varied functionalities into a single chip, providing a tailored solution for complex electronic systems.

Integration Density:

· ICs: The miniaturization of components on a semiconductor wafer enables the creation of densely packed ICs with high integration density. This is especially crucial in applications where space is a premium, such as mobile devices and consumer electronics.

· Chips: Chips, as a broader category, may or may not exhibit the same level of integration density as individual ICs. Depending on the specific requirements of the application, chips can have varying levels of complexity and integration.

System Complexity and Size:

· ICs: ICs contribute to the complexity of electronic systems by performing specialized functions. They allow for the creation of sophisticated systems with optimized performance for specific tasks.

· Chips: The use of chips, which may house multiple ICs, can simplify the overall system design. By integrating multiple functions into a single package, chips can reduce the complexity of interconnecting individual ICs on a circuit board, leading to more compact and streamlined electronic systems.

In summary, while integrated circuits represent the fundamental building blocks of electronic systems with specific functionalities, chips offer a more comprehensive solution by integrating multiple ICs and components. The choice between using discrete ICs or chips depends on the specific requirements of the application, balancing factors such as functionality, customization, and integration density.

Conclusion:

In summary, while integrated circuits and chips are intimately related, they represent distinct concepts in the realm of electronics. Integrated circuits refer specifically to miniature electronic circuits fabricated on a semiconductor wafer, emphasizing their role in performing specific functions. On the other hand, chips encompass a broader range of semiconductor devices, including integrated circuits, and may serve multiple functions within a single package.

Understanding these differences is crucial for both electronics enthusiasts and professionals, as it lays the foundation for comprehending the intricacies of modern electronic systems and the components that drive technological innovation. As technology continues to evolve, the clear distinction between integrated circuits and chips remains fundamental to unlocking the full potential of electronic devices in the years to come.

Subscribe to Us !

-

LV71081E-MPB-E

LV71081E-MPB-Eonsemi

-

LMK00334RTVRQ1

LMK00334RTVRQ1Texas Instruments

-

PI6C557-03LEX

PI6C557-03LEXDiodes Incorporated

-

PCM1753DBQR

PCM1753DBQRTexas Instruments

-

ADS1204IRHBT

ADS1204IRHBTTexas Instruments

-

MCP4018T-104E/LT

MCP4018T-104E/LTMicrochip Technology

-

T4F49C2

T4F49C2Efinix, Inc.

-

.jpg) A40MX02-PLG44

A40MX02-PLG44Microchip Technology

-

ATF16V8C-7PU

ATF16V8C-7PUMicrochip Technology

-

SC-13048Q-A

SC-13048Q-AGHI Electronics, LLC