Evaluating the Strategic Gap in Supply Chain Management

Introduction:\

Supply chain management is a critical aspect of any business that involves the movement of goods or services from production to consumption. It plays a significant role in ensuring a smooth flow of operations, optimizing costs, and enhancing customer satisfaction. However, despite its importance, many organizations face challenges in managing their supply chains effectively. This blog post will evaluate the strategic gap in supply chain management, examining the reasons behind it and providing insights on how businesses can bridge this gap to achieve operational excellence.

Understanding the Strategic Gap:\

The strategic gap in supply chain management refers to the disparity between the desired state of the supply chain and its actual performance. This gap often arises due to several factors, including inadequate planning, lack of integration, poor communication, and insufficient technological infrastructure. When left unaddressed, this gap can result in delayed deliveries, increased costs, low product quality, and dissatisfied customers.

Factors contributing to the Strategic Gap:

1. Inadequate Planning: One of the primary reasons for the strategic gap is inadequate supply chain planning. This includes factors such as inaccurate demand forecasting, insufficient inventory management, and ineffective procurement strategies. Without a solid planning foundation, businesses are likely to face disruptions and inefficiencies in their supply chains.

2. Lack of Integration: Many businesses struggle with integrating different components of their supply chain. This lack of integration leads to siloed operations, disjointed workflows, and difficulties in achieving end-to-end visibility. A fragmented supply chain inhibits collaboration and hampers overall performance.

3. Poor Communication: Effective communication is vital in supply chain management, as it facilitates coordination and enables quick decision-making. When communication channels are weak, information gets lost, leading to misalignment between stakeholders. Clear and transparent communication is crucial to address issues promptly and minimize disruptions.

4. Insufficient Technological Infrastructure: In today's highly digitalized world, businesses need robust technological infrastructure to manage their supply chains efficiently. Outdated systems, lack of automation, and inadequate data analytics capabilities hinder organizations from gaining real-time insights and leveraging technology to optimize their operations.

Closing the Strategic Gap:\

To bridge the strategic gap in supply chain management, organizations need to adopt a proactive approach and implement the following strategies:

1. Demand-driven Planning: Investing in advanced demand forecasting methods, such as predictive analytics, can help businesses anticipate customer demand more accurately. This enables them to adjust production levels, optimize inventory, and reduce the risk of stock-outs or overstocking.

2. Supply Chain Integration: Embracing supply chain integration enables seamless collaboration across departments, suppliers, and customers. Businesses should strive to create a cohesive network that allows for real-time information sharing and better decision-making.

3. Enhanced Communication: Establishing effective communication channels within the supply chain is crucial. This includes implementing robust communication tools, regular meetings, and sharing performance metrics to foster transparency and collaboration.

4. Leveraging Technology: Investing in advanced supply chain technologies, such as cloud-based platforms, Internet of Things (IoT) devices, and artificial intelligence (AI), can significantly enhance supply chain efficiency. These technologies offer real-time visibility, automate processes, and provide valuable insights for strategic decision-making.

5. Continuous Improvement: The strategic gap in supply chain management cannot be closed overnight. It requires a commitment to continuous improvement, monitoring key performance indicators, and adapting to changing market dynamics. Regular evaluation and refinement of supply chain processes are essential to ensure ongoing optimization.

Case Study: XYZ Company's Journey to Bridge the Strategic Gap\

To further illustrate the concept of bridging the strategic gap in supply chain management, let's consider the case of XYZ Company, a global manufacturing firm. XYZ Company faced challenges related to inventory management, which resulted in frequent stock-outs and customer dissatisfaction. Recognizing the need for improvement, the company implemented an integrated supply chain planning system and adopted advanced demand forecasting techniques. This allowed them to streamline their inventory levels and improve customer service levels significantly. By leveraging technology and focusing on continuous improvement, XYZ Company successfully bridged the strategic gap in their supply chain management, leading to increased efficiency and customer satisfaction.

In conclusion, managing the strategic gap in supply chain management is crucial for businesses seeking operational excellence. By addressing key factors such as inadequate planning, lack of integration, poor communication, and insufficient technological infrastructure, organizations can bridge this gap and ensure a streamlined and efficient supply chain. Continuous improvement, leveraging technology, and fostering collaboration are essential components of this journey. With a proactive approach and a commitment to optimization, businesses can achieve their supply chain goals and deliver value to their customers.

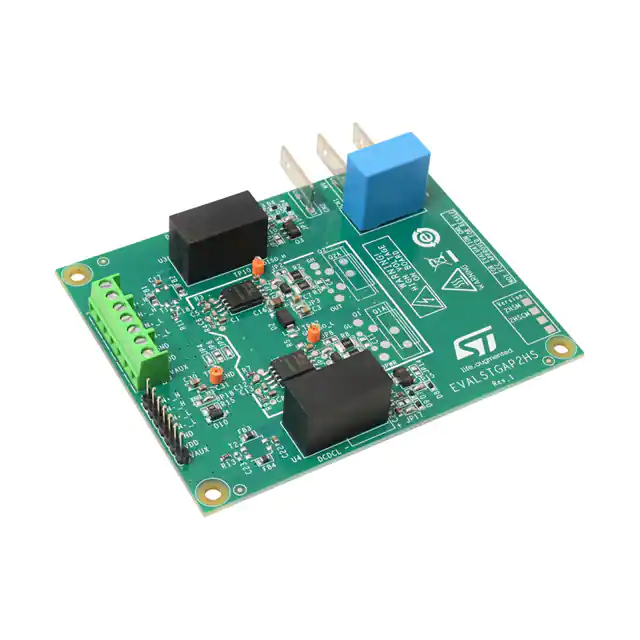

EVALSTGAP2HSCM

- Part Number :

- EVALSTGAP2HSCM

- Manufacturer :

- STMicroelectronics

- Description :

- EVAL BOARD FOR STGAP2HSCM

- Datasheet :

-

EVALSTGAP2HSCM.pdf

EVALSTGAP2HSCM.pdf

- Unit Price :

- Request a Quote

- In Stock :

- 3692

- Lead Time :

- To be Confirmed

- Quick Inquiry :

- - + Add To Cart

Request a Quote

EVALSTGAP2HSCM Specifications

EVALSTGAP2HSCM Guarantees

-

Service Guarantees

We guarantee 100% customer satisfaction.

Our experienced sales team and tech support team back our services to satisfy all our customers.

-

Quality Guarantees

We provide 90 days warranty.

If the items you received were not in perfect quality, we would be responsible for your refund or replacement, but the items must be returned in their original condition.

Certified Quality

View the Certificates

View the Certificates