BCP56-16 Compliance: What You Need to Know

BCP56-16 is a standard that ensures proper thermal management of LED lighting systems. The compliance with BCP56-16 ensures the longevity and reliability of any LED lighting system, which makes it a crucial aspect to consider for anyone developing LED lighting systems.

In this blog post, we will discuss the significance of BCP56-16 compliance, its requirements, benefits, and the steps to achieve it.

What is BCP56-16?

The BCP56-16 is a document that outlines the testing and qualification procedures of LED lighting systems. It also specifies the key parameters that must be met to ensure proper thermal management of the lighting system.

The document was developed by the Solid-State Lighting Technology Working Group of the US Department of Energy (DOE) in response to the growing demand for LED lighting systems. The purpose of the document is to ensure that LED lighting systems are properly designed and qualified to ensure performance, reliability, and efficiency.

Why is BCP56-16 Compliance Important?

The compliance with BCP56-16 ensures that LED lighting systems meet the required thermal performance criteria. This means that the system is designed to handle the heat generated by the LED sources.

The excessive heat can reduce the LED's lifespan and cause permanent damage to the lighting system. Therefore, the thermal management of the lighting system is crucial to ensuring the system's longevity and reliability.

Requirements for BCP56-16 Compliance

To comply with BCP56-16, the LED lighting system must undergo specific testing processes. These testing procedures include:

1. Photometric Testing

This involves measuring the light output of the LED lighting system. The test is conducted in an integrating sphere and measures the luminous flux, color, and color rendering index.

2. Electrical Safety Testing

This testing procedure verifies that the LED lighting system is safe to use and complies with various safety standards. The test includes a high-potential test, a ground continuity test, and leakage current tests.

3. Thermal Testing

This procedure measures the temperature of the LED lighting system. The test ensures that the LED lighting system can adequately dissipate heat generated by the LED sources.

4. Life Testing

This testing procedure verifies the reliability and longevity of the LED lighting system. The test simulates the lifespan of the lighting system in real-world conditions, according to the Standards.

5. Environmental Testing

The environmental testing procedure verifies that the LED lighting system can handle extreme environmental conditions. The test includes high and low-temperature testing, humidity testing, and vibration testing.

To achieve BCP56-16 compliance, the LED lighting system must pass each of these testing procedures.

Benefits of BCP56-16 Compliance

There are several benefits of complying with the BCP56-16 standard:

1. Improved System Performance

By complying with BCP56-16, the LED lighting system's performance is improved, ensuring that it meets the required thermal performance criteria.

2. Increased System Reliability

The BCP56-16 compliance ensures that the LED lighting system is reliable, reducing the risk of breakdown and problems down the line.

3. Reduced Maintenance Costs

The thermal management of the LED lighting system is critical to reducing maintenance costs. Complying with BCP56-16 ensures that the system has a long lifespan, meaning fewer replacements and repair costs.

Steps to Achieve BCP56-16 Compliance

To achieve BCP56-16 compliance, there are specific steps that designers and manufacturers must follow:

1. Understand the Standards

The first step is to understand the BCP56-16 compliance standards. This involves studying and interpreting the set Standards and ensuring that the LED lighting system meets all the requirements.

2. Conduct Specific Tests

Once the Standards are understood, the specific tests required to achieve compliance can begin. These tests include photometric testing, electrical safety testing, thermal testing, life testing, and environmental testing.

3. Report Results

The testing results should be recorded and shared with the relevant parties, including designers, manufacturers, and regulators.

4. Take Action

Finally, if any issues or errors are identified, correction actions should be taken to ensure that the system achieves compliance.

Conclusion

In conclusion, BCP56-16 compliance is a crucial aspect that anyone designing or manufacturing LED lighting systems must consider. The compliance process involves specific testing procedures that ensure that the LED lighting system meets the required standards for thermal management. Achieving BCP56-16 compliance not only improves the system's performance and reliability but also reduces maintenance costs, making it a worthwhile investment for anyone in the LED lighting industry.

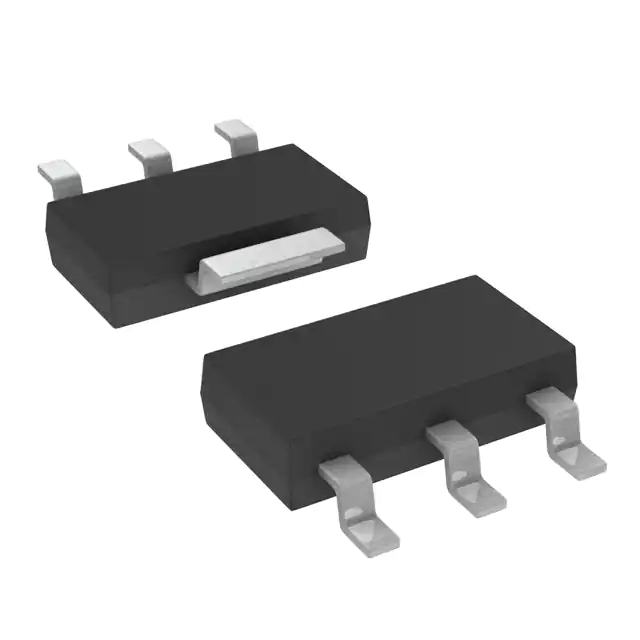

BCP56-16

- Part Number :

- BCP56-16

- Manufacturer :

- STMicroelectronics

- Description :

- TRANS NPN 80V 1A SOT223

- Datasheet :

-

BCP56-16.pdf

BCP56-16.pdf

- Unit Price :

- Request a Quote

- In Stock :

- 2874

- Lead Time :

- To be Confirmed

- Quick Inquiry :

- - + Add To Cart

Request a Quote

BCP56-16 Specifications

- Packaging:

- Tape & Reel (TR),Cut Tape (CT)

- Series:

- -

- ProductStatus:

- Active

- TransistorType:

- NPN

- Current-Collector(Ic)(Max):

- 1 A

- Voltage-CollectorEmitterBreakdown(Max):

- 80 V

- VceSaturation(Max)@IbIc:

- 500mV @ 50mA, 500mA

- Current-CollectorCutoff(Max):

- 100nA (ICBO)

- DCCurrentGain(hFE)(Min)@IcVce:

- 100 @ 150mA, 2V

- Power-Max:

- 1.6 W

- Frequency-Transition:

- -

- OperatingTemperature:

- 150°C (TJ)

- MountingType:

- Surface Mount

BCP56-16 Guarantees

-

Service Guarantees

We guarantee 100% customer satisfaction.

Our experienced sales team and tech support team back our services to satisfy all our customers.

-

Quality Guarantees

We provide 90 days warranty.

If the items you received were not in perfect quality, we would be responsible for your refund or replacement, but the items must be returned in their original condition.

Certified Quality

View the Certificates

View the Certificates